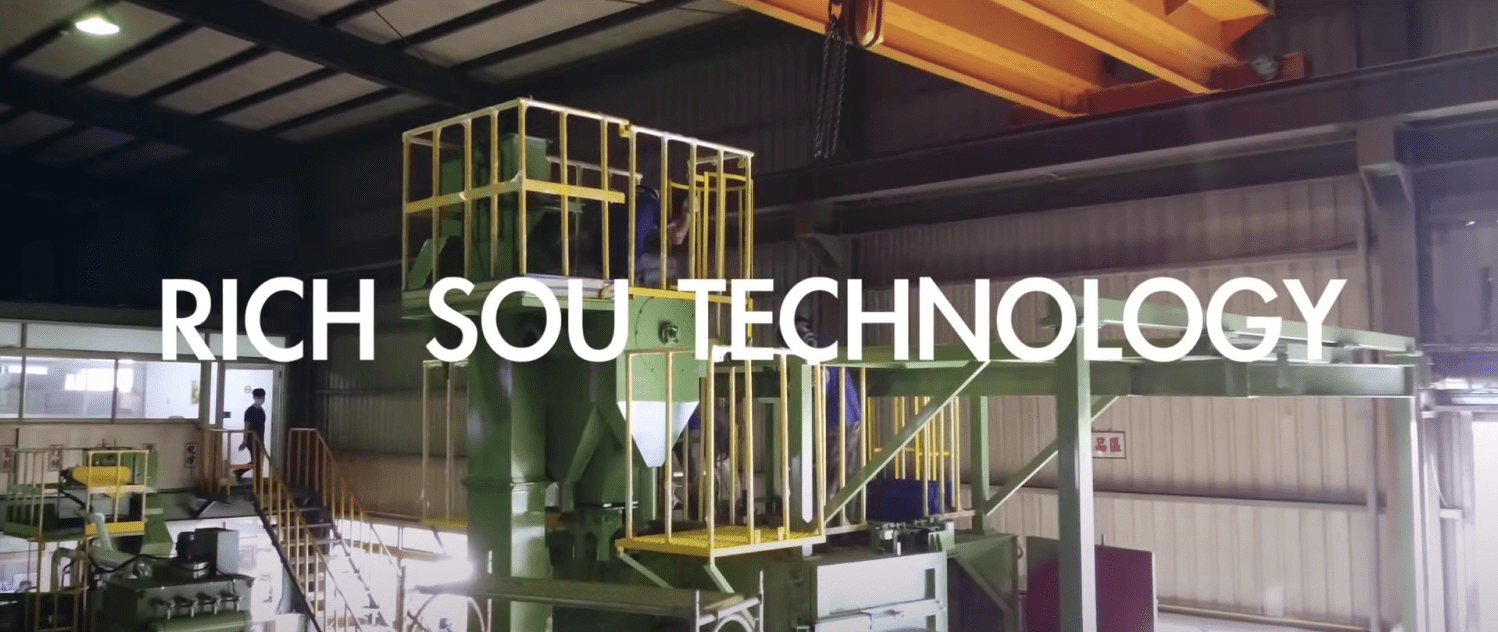

Rich Sou Co., Ltd. is the most professional manufacturer, blasting machinery, shot peening machinery, stress relief machinery, IC mold clean system, auto recovery system blast room, and Dust collector and so on. Also, Rich Sou is agent of blasting abrasives in Asia. Rich Sou holds the principles of best quality, advanced technique, customer satisfaction and sustainable management. Since, we believe that best quality will beneficial for marketing. Rich Sou creates high valve and high quality products to lead marketing and make advantage. In 1996, Rich Sou won the CE Certification; it means that we got the international quality certification. Also, we won Taiwan Casting Innovation Award and 2015 Taiwan Excellence Award and so on, conduces to branch out our market to Europe and America.

Product

Open for

The World

Integrated

With Asia

Based In

Taiwan